SS 316L BX155 Ring Joint Gasket

We have all range materials of Stainless steel for BX Ring Joint gasket such as SS 316L, SS 304, SS 321

Content

BX155 Ring Joint Gasket

SS 316L BX155 ring joint gasket is made of AISI 316L grade stainless steel. And for type BX ring joint gasket, it is actually rectangular in cross section and tapers in each corner in addition to it has a strain balance hole to make certain equalization of pressure which might be trapped in the grooves. BX ring Gaskets have been suitable for higher pressure ratings starting at 5,000 lbs, and ending with 20,000 lbs.Regarding to SS 316L, often referred to as 304 stainless-steel or marine class stainless-steel, may be the secondly most popular austenitic stainless after 304 steel. Its main alloying ingredients after iron, are chromium (between 16 to 18%), nickel (10 – 12%) and molybdenum (2–3 Percent), with tiny (less 1%) levels of silicon, phosphorus and sulfur also existing. Adding molybdenum offers higher corrosion opposition than 304, when it comes to local corrosive assault by chlorides as well as common rust by reducing acids, such as sulfuric acid solution. SS 316L grade will be the low carbon dioxide variation of 316 stainless steel. When frosty did the trick, 316 can develop great yield and tensile strong points comparable to Duplex stainless level.

The Difference Between 316 and 316L Stainless Steel

The difference between 316 and 316L stainless steel is that 316L has a 0.03% maximum carbon content by weight while 316 stainless steel had a 0.08% maximum carbon content.Both 316 and 316L also contain some chromium, nickel and molybdenum which make both 316 and 316L stainless steels especially corrosion resistant. The lower carbon content of 316L gives it an even greater resistance to corrosive environments than 316 stainless steel.

The lower carbon content of 316L stainless steel also makes it easier to weld than 316 stainless steel. Both of these alloys have excellent welding properties and can be welded using either fusion or resistance welding techniques.

SS316L Chemical Composition (%)

| UNS | Grade | C ≤ | SI ≤ | MN | P | S | NI | CR | Mo |

| UNS S31600 | 316L | 0.03 | 1 | 2 | 0.045 | 0.03 | 10 to 14 | 16 to 18 | 2.0 - 3.0 |

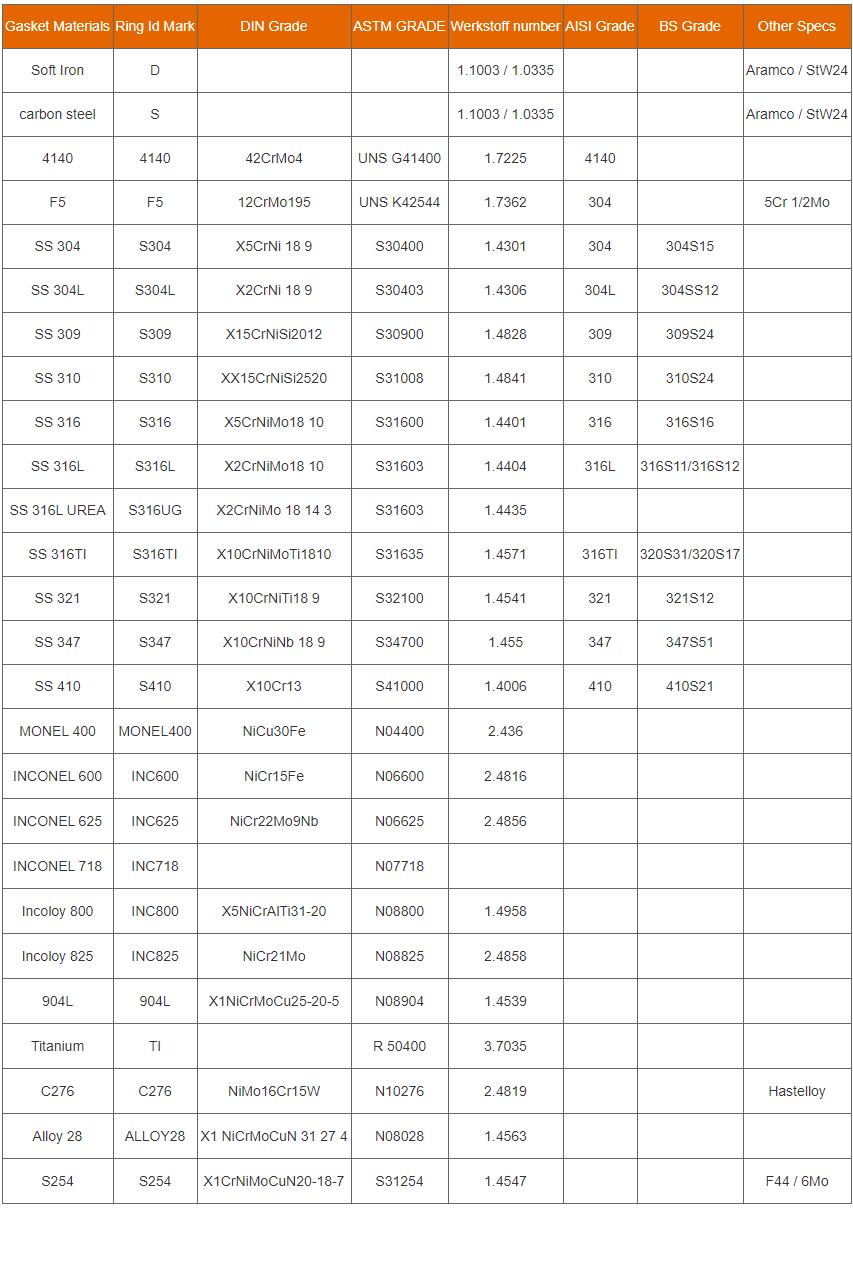

RTJ Gasket Materials Charts

Related Category

Cutting Metal Gasket Washer

Octagonal Ring Joint Gasket

Oval Ring Joint Gasket

BX Ring Joint Gasket

RX Ring Type Joint Gasket

IX Seal Ring Joint Gasket

Lens Ring Type Joint Gasket

AX or CX and VX Ring Gasket

Spiral Wound Gasket

Related Products